Environmental Product Declaration (EPD) Certification

The Environmental Product Declaration (EPD), also referred to as Type III Environmental Declaration, is a globally acknowledged independent verification process based on ISO14025 “Environmental Labeling and Declaration-Type III Environmental Declaration-Principles and Procedures.” It serves as a comprehensive disclosure of the environmental impact of products throughout their entire life cycle, offering scientific and comparable information.

Who is Concerned?

The individuals or groups who are interested in communicating their environmental performance globally using a recognized and valid instrument include both public and private stakeholders. This encompasses a wide range of individuals, organizations, and entities.

Why need environmental product declaration?

Environmental product declarations can help enterprises:

- Improving environmental decision-making

- Quantify the performance of enterprises in environment

- Promote green consumption

- Highlight corporate social responsibility

- Break through international trade barriers

- Enhance corporate brand image

Applicable Standards and Technical Requirements of EPD

ISO 14020 “General Principles for Environmental Labelling and Declaration”

ISO 14025, Type III Environmental Declaration

ISO 14040, Life Cycle Assessment – Principles and Procedures

ISO 14044, Life Cycle Assessment – Requirements and Guidance

Applicable PCR of product

Steps to Perform EPD

The development of the EPDs will be performed based on the following steps:

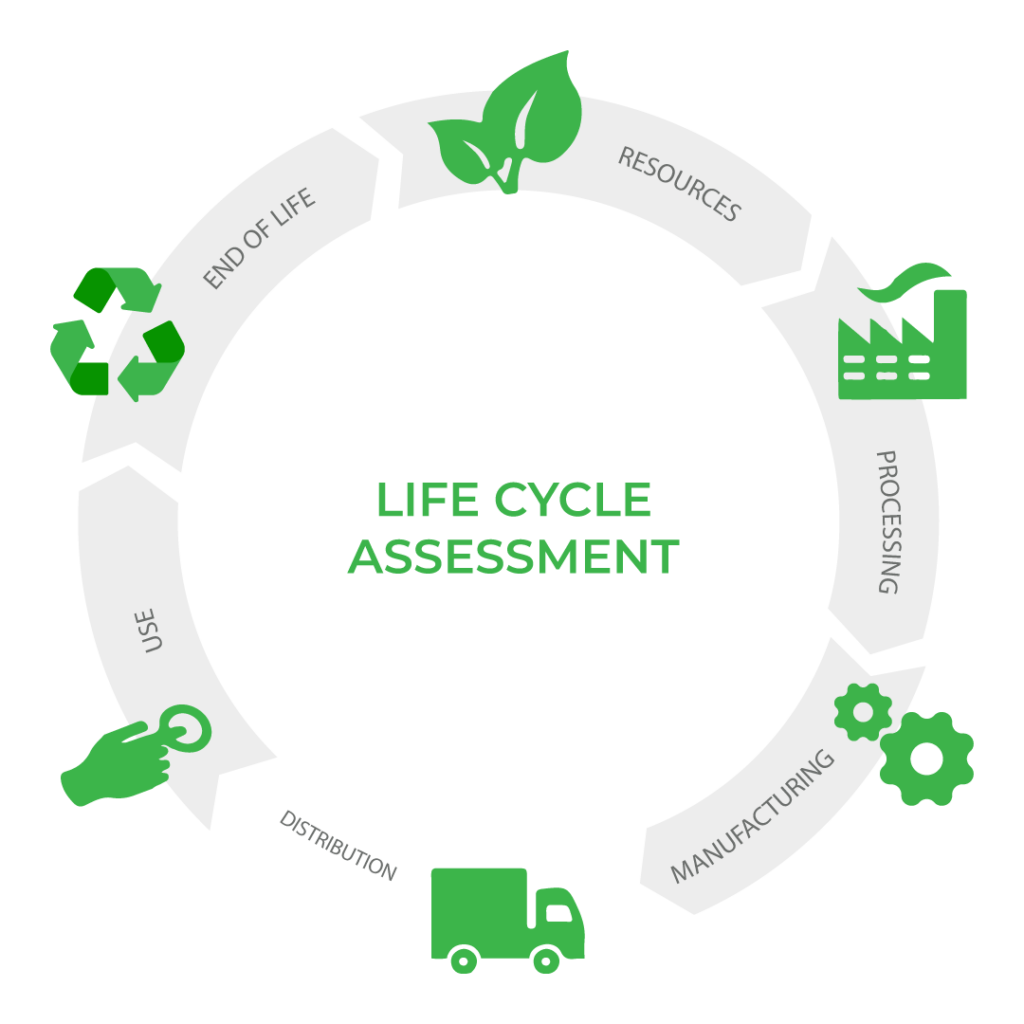

First step: Life Cycle Analysis

The first stage includes the development of an LCA (Life Cycle Analysis) for the specific products, taking into account ISO 14040 and ISO 14044 as well as the PCR (Product Category Rules). The LCA will include specific stages of the life cycle taking into account the mandatory stages provided by the standards. Based on this data, a Life Cycle Analysis report (LCA Report) will be developed.

In order to perform the LCA, the following data must be collected for each one of the factories and all the calculations will be performed for each factory separately:

- Determining the reference year: We need to decide the year for which we need to collect the data.

- Total production quantity for the reference year

- Quantity in kilograms of specific products included in EPDs for the reference year.

- Product’s CPC code.

- Product’s EN code.

- Description of the production procedure.

- Factory’s electricity consumption for one reference year.

- Fuel consumption (e.g., diesel) for product production in the factory, including the use of diesel fuel for Clark equipment, based on invoices for one reference year.

- Total water consumption based on invoices.

- Annual raw material consumption for the production of specific products included in the EPDs, indicated as the quantity of raw materials in kilograms per kilogram of product.

- Technical Data Sheets (TDS) and Safety Data Sheets (SDS) for all raw and secondary materials. For steel, the origin of steel is important, including the percentage of production from scrap material.

- Packaging materials used for specific products included in the EPD, including film, PP, pallets, hoops, etc. Provide the weight of each package and the capacity or quantity of packages in kilograms per kilogram of products.

- Transportation of raw materials and packaging materials from suppliers to your facility: indicate the means of transport/transportation methods used.

- Quantities and types of gaseous emissions, liquid waste, and solid waste generated during the production of the products.

- Waste management practices.

- Transportation of products to final users.

Second step: Calculation of environmental impact indicators for each product or group of products using a software

For each stage of the LCA, specific environmental impact indicators will be calculated, which are specified in the standards. The impact assessment is carried out for the following impact categories:

- Acidification

- Climate change

- Depletion of abiotic resources (ADPE)

- Eutrophication

- Ozone depletion

- Photochemical ozone formation

- Water use

- Output flows

- Resources – Energy

These parameters will be calculated per kg of product and at every stage.

For the development of indicators, recognized databases will be used as well as specific data from the production of the industrial units. Based on this data, appropriate calculations will be made for each stage using an appropriate Life Cycle Analysis calculation model (appropriate software).

Third step: Development of EPDs

The third step includes the development of EPDs. The outcome of the LCA will be presented in the form of a Declaration based on the requirements and specifications of the EPD standards. As mentioned above the number of EPDs to be generated depends on the different types of products and the variation of environmental parameters.

Fourth step: EPD Verification

An EPD verification will be performed. Our company will participate in the verification procedure.